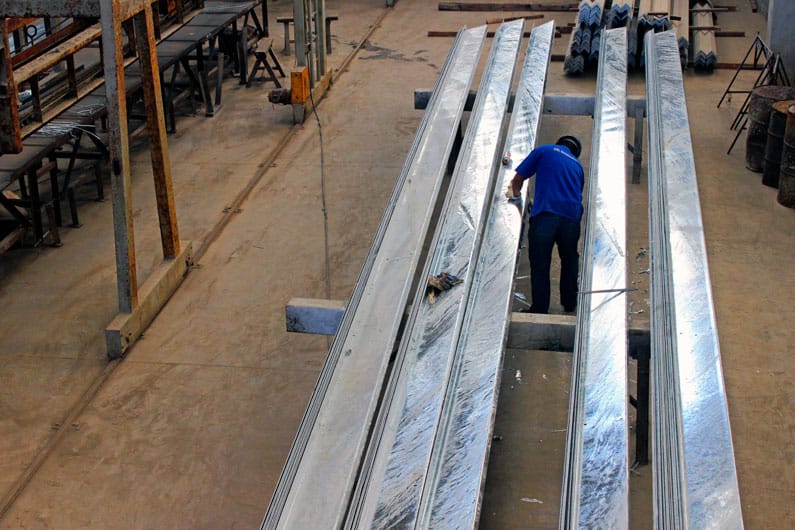

GALVANIZATION SERVICES

Hot-dip galvanizing

The process:

It is called HOT-DIP GALVANIZING the process of cleaning and subsequent dipping of iron or steel pieces into liquid zinc.

Under de regular conditions of GALVANIZING, during the immersion, several layers of Zn-Fe alloy are formed, and the last one (external) is constituted by pure zinc.

All types and shapes of steel, iron or cast iron can be galvanized with the following advantages:

– Zinc corrodes only 3 to 10% in relation to bare steel exposed to air and corrosion speed is known for several kinds of atmosphere, in way that maintenance-free lifetime can be safely stablished.

– The Zn-Fe alloy layer, in between metal base and zinc’s external layer, is almost as hard as steel, in which the resistance of the coating is noticed.

Details about our services:

Fundada em 1994, a GSL METALÚRGICA S.A. é uma empresa especializada na galvanização a fogo de produtos de aço, tendo desenvolvido as melhores técnicas para atender às mais variadas demandas deste mercado.

Estes serviços são executados por equipe especializada e seguem as normas especificadas pelo cliente, atendendo o mais alto padrão de qualidade e acabamento.

Garantimos a qualidade de nossos produtos e serviços conforme preconizado nas principais normas internacionais e brasileiras vigentes.

Dentre os diversos produtos que galvanizamos, destacamos:

General metallic structures for electrical power transmission lines, substation and telecommunications;

Ironwork for lightning rod system, retention components, bolt and nuts;

Cast iron and other products on demand;

Metallic tubes, such as: irrigation, structures for traffic signals, electrification and illumination;

Metallic structures for industrial buildings, residences, naval area, bridges, railway components and metallic parts in general.

About our structure and certification

GSL METALÚRGICA S.A. has a high-level professional staff, with enough infrastructure to meet the multiple demands. With its own headquarters, 70.000 m² area, warehouses with necessary equipment for cargo handling, raw material and finished products storage area, a 60-ton capacity weighbridge.

Our modern galvanization system has electronic temperature and process control. The capacity is for 2.300 tons/month.

ISO 9001 certified industry, having all the galvanization process according to NBR 6323 e ASTM A123 standards. We assure absolute punctuality in stated delivery times.

Request a quote

Phone: +55 31 3679-3100